Project Objective

The goal of this project was to reduce the cost, assembly time, and manufacturing time of Embrace Innovation's Infant Care Unit by redesigning the heater module (a.k.a. the Smart Pak).

Participants

Jasmine Lee, Catherine Tran, Emily Sataua, and José Gutierrez completed this project during the spring of 2013. All four members were equally involved in the ideation, fabrication, testing, and analysis phases of this project.

Existing Product Dissection

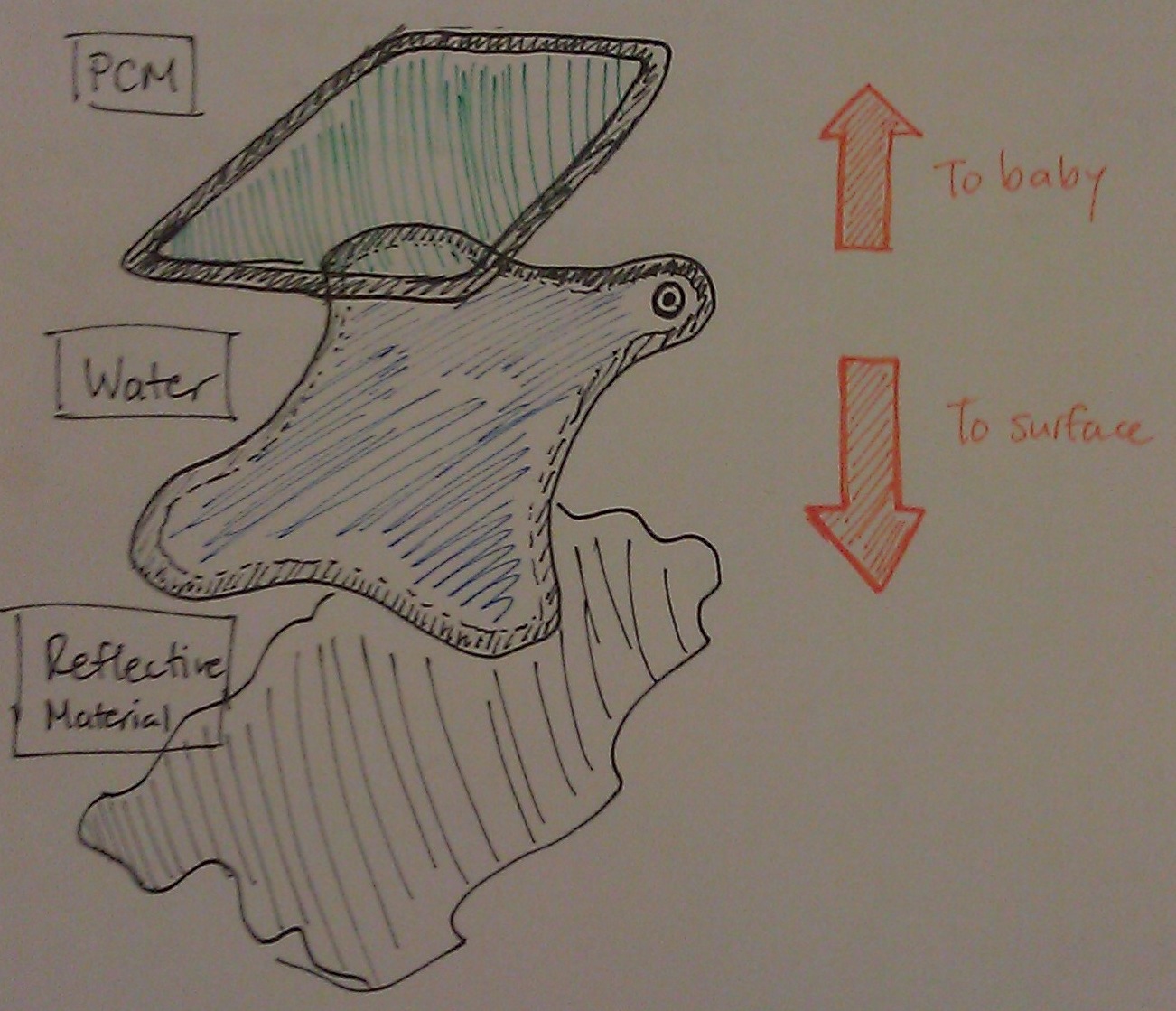

To operate the original Infant Care Unit:

- Pour boiling water into Smart Pak

- Phase Change Material (PCM) melts

- PCM maintains a temperature of 37ºC

The original Smart Pak consisted of seven layers of material. The Smart Pak redesign focus became finding a more efficient way to keep the baby warm to reduce the amount of money and time invested per product.

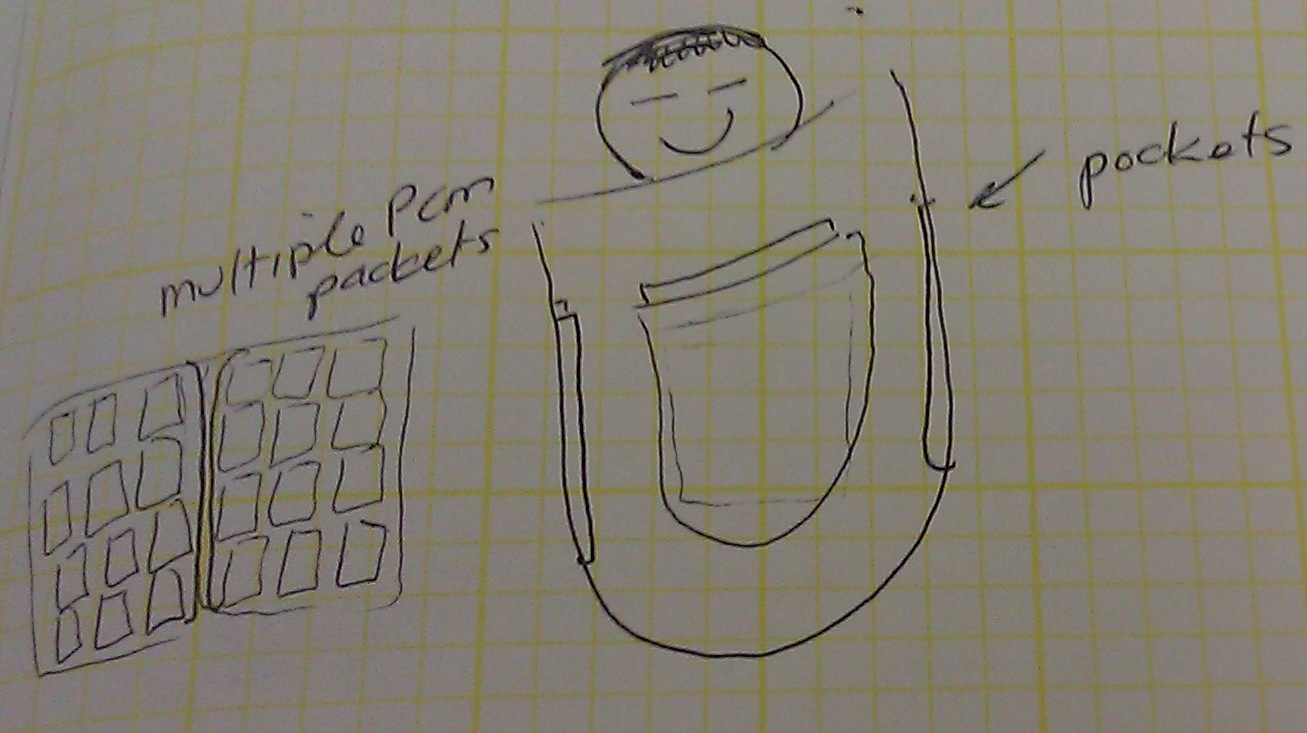

Ideation

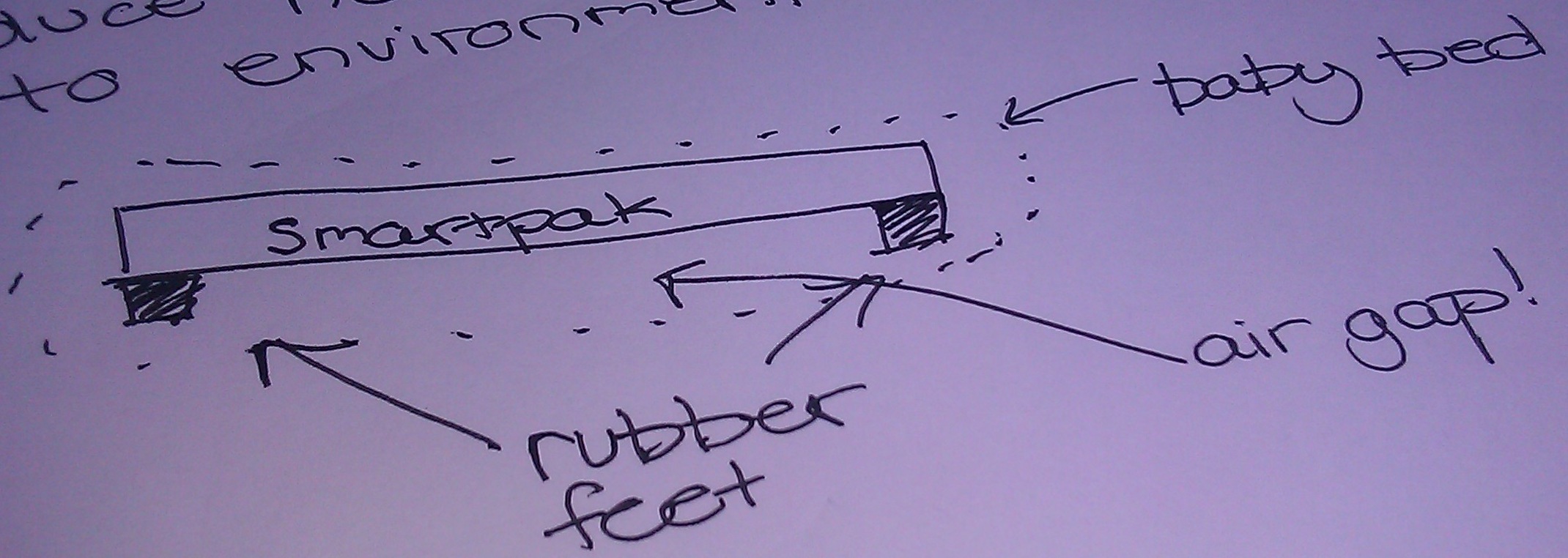

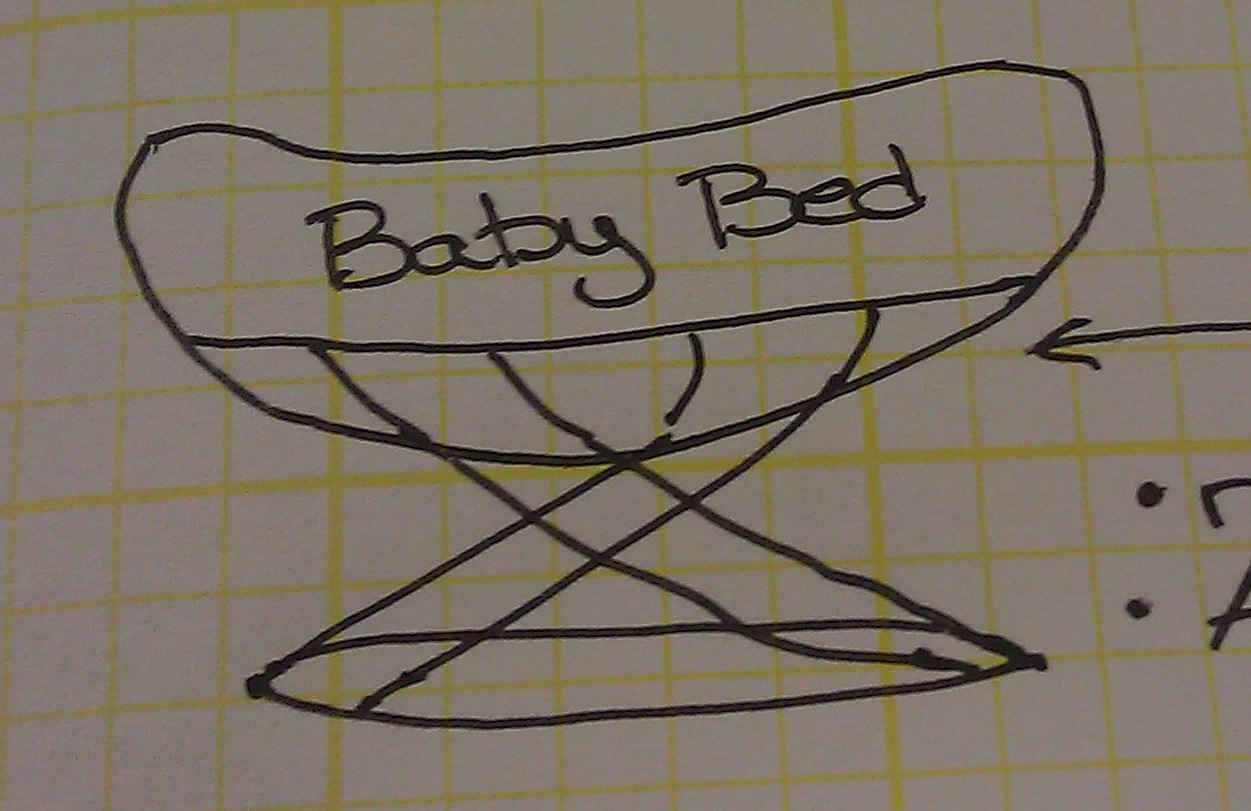

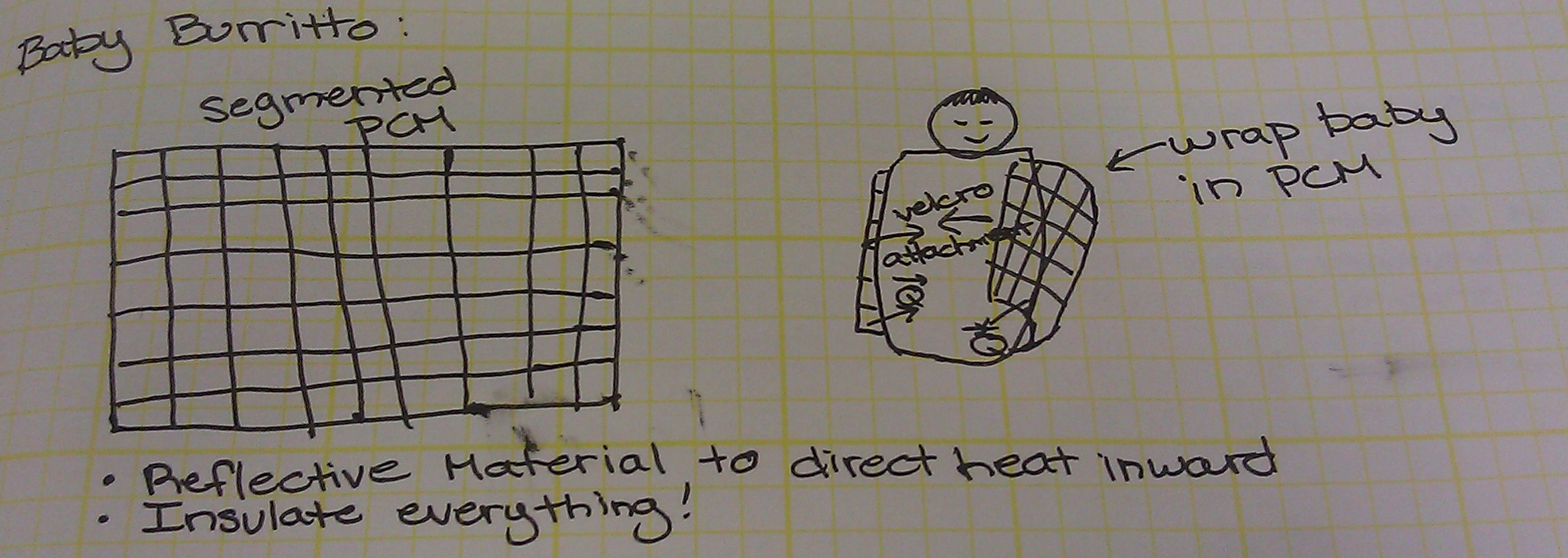

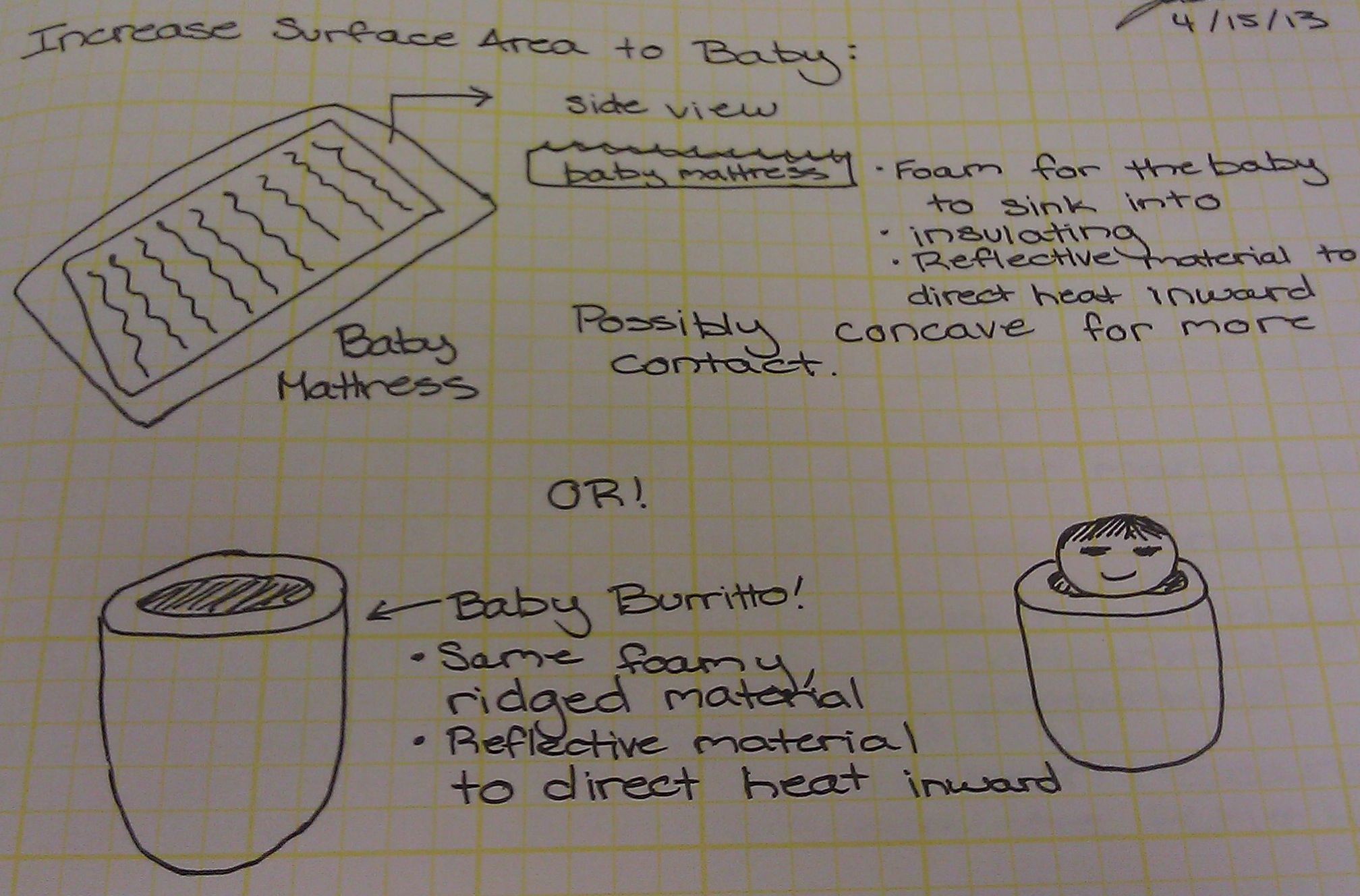

This brainstorm focused on efficiently transferring heat from the PCM to the infant. The most viable option proved to be a Smart Pak that kept the size and shape of the original pack so that Embrace Innovations could continue to use the original Infant Care Unit bed.

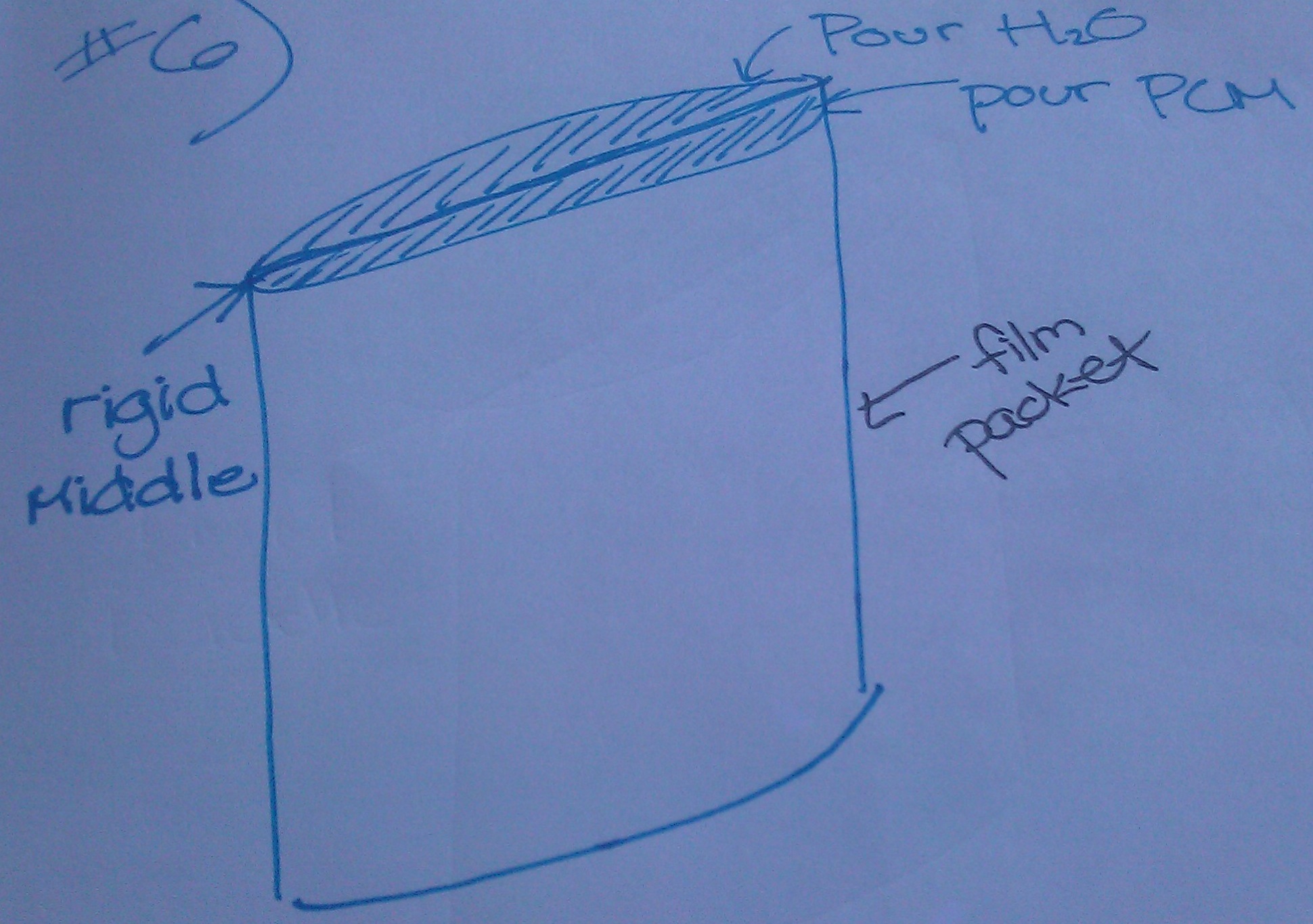

Smart Pak Prototypes

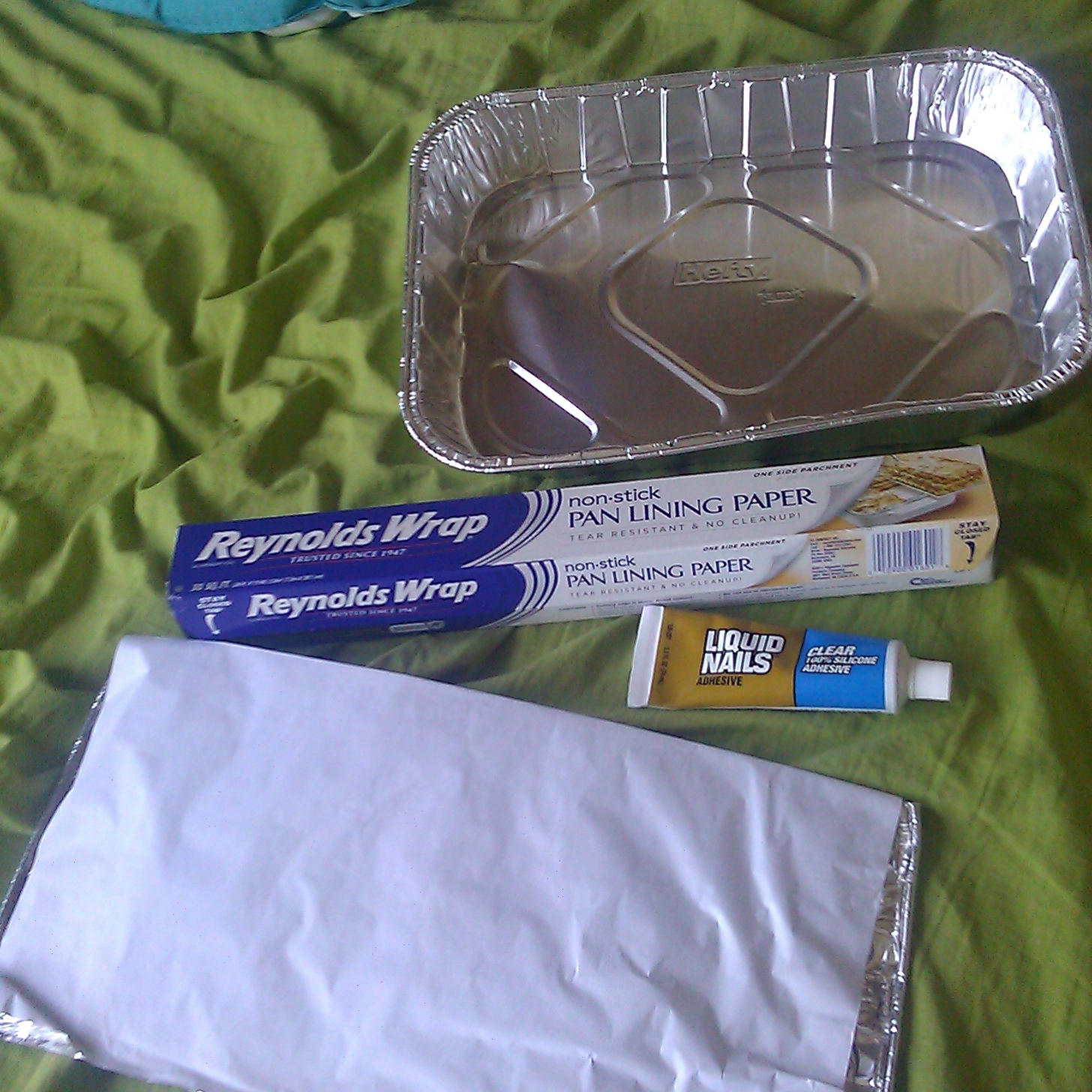

Embrace used aluminum laminate, adhesives, and a heat sealing process to create the original Smart Pak, so the preliminary prototypes used those as well.

Prototype #1

- Adhered aluminum foil to an aluminum sheet

- Demonstrates the overall form

Prototype #2

- Heat-sealed vinyl with an aluminum sheet

- Experimented with heat-sealing plastic to metal

Final Result

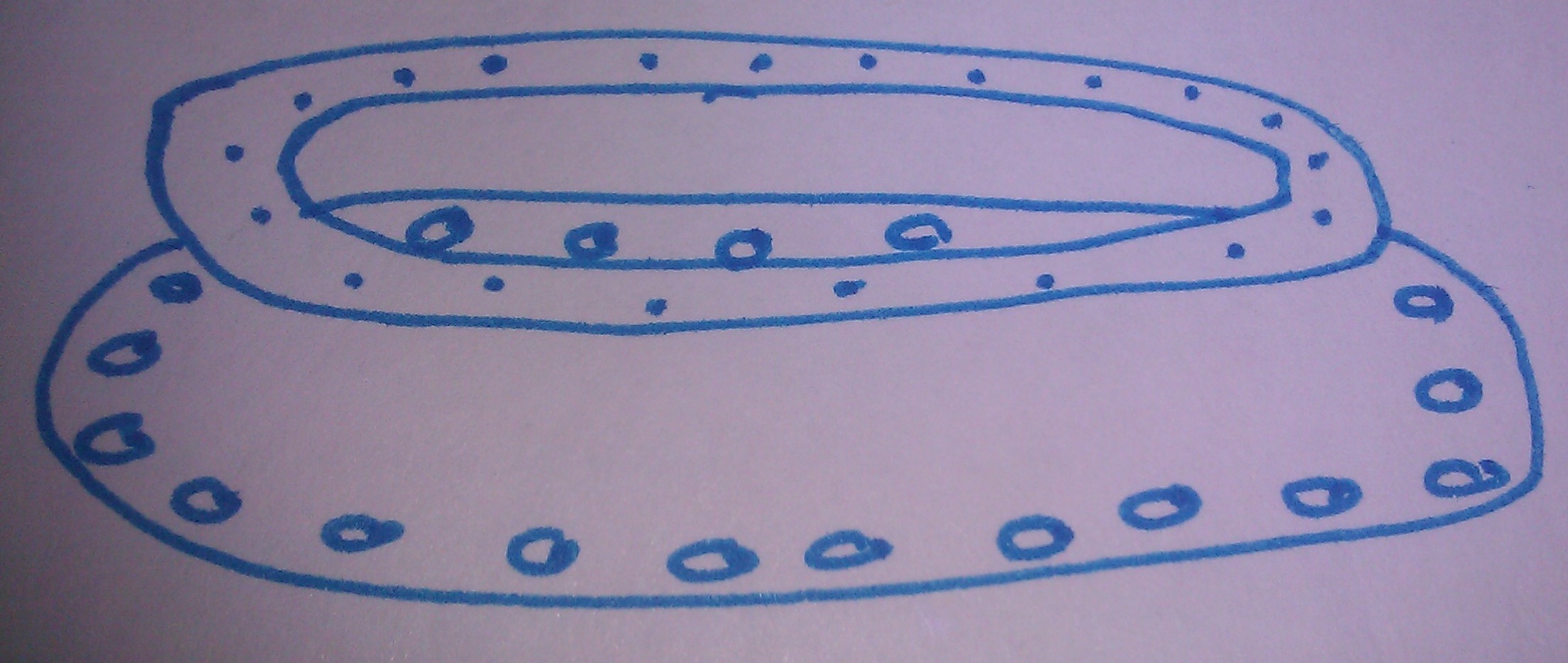

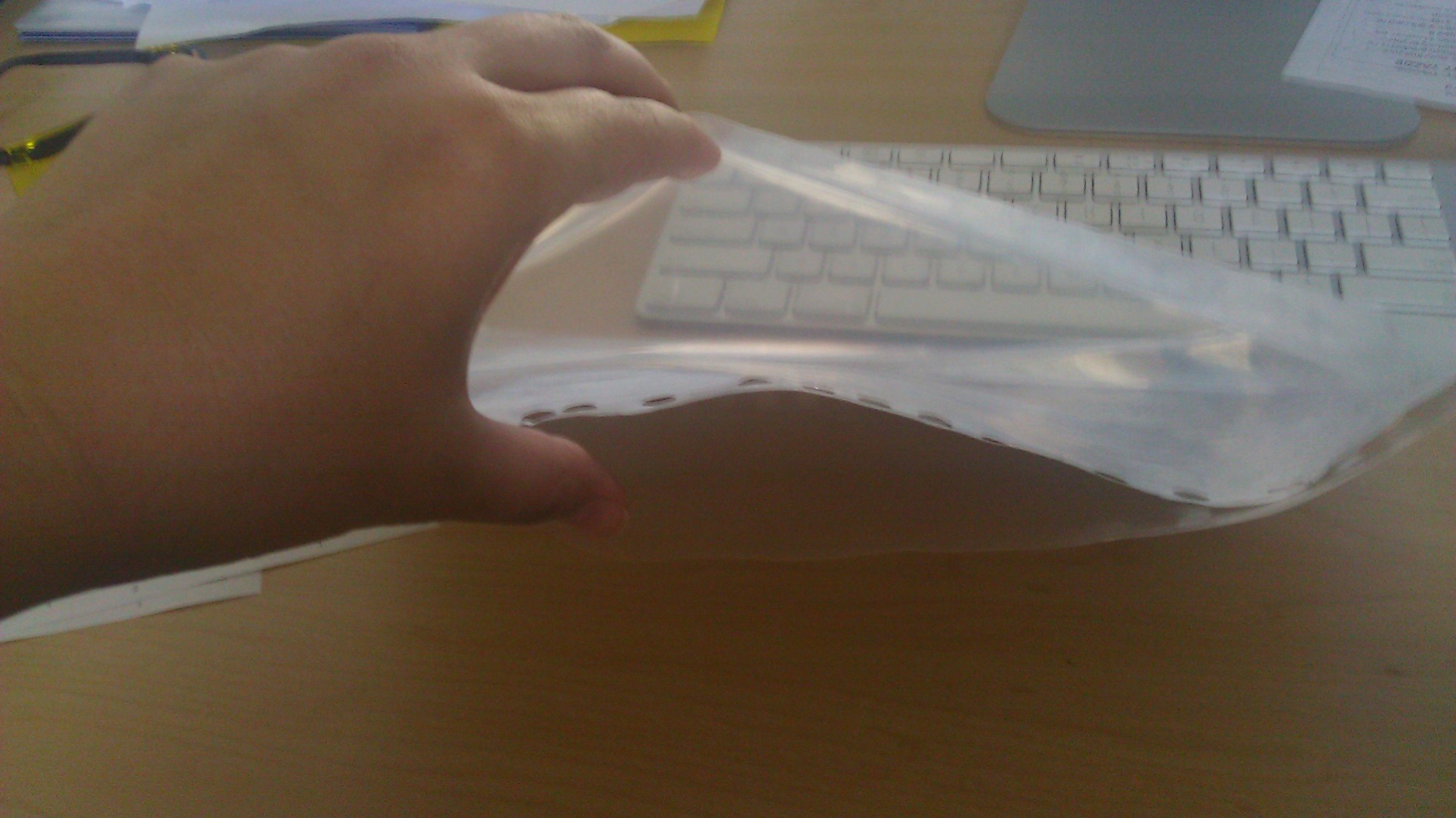

Functional Smart Pak Prototype

- Vinyl, aluminum, water, and the PCM material

- Aluminum: rigid, heat conducting layer

- Vinyl: demonstrated the effectiveness of heat seals at holding both the water and PCM

- Improved functionality achieved

When manufactured with the recommended three layers of aluminum laminate, the product would be further improved functionally and meet the cost reduction goals of Embrace Innovations.

Left to right: solid pcm - melted pcm - funneling pcm into final prototype - josé testing final prototype